Magnesium Oxide Board

description1

description2

Key Features & Performance

MGO BOARD contributes to a more efficient, profitable, environmentally and health-friendly construction production. It has excellent fire and sound properties, sensitive to moisture, very shock-resistant and produced entirely without environmentally and health-hazardous raw materials. This board is very easy to process, and can be advantageously cut and broken as a plasterboard.

In many applications, MgO boards can be used in the same ways as gypsum and Portland cement sheathings. The substitution is not fully direct in terms of sheet thicknesses, fastening methods and joint treatments, but is very similar. This makes MgO board an easy product to use. The possible uses of MgO board are vast, and some of them include:

● In heat insulation as an exterior side coating

● In partition wall systems in interior locations (6-2mm)

● In construction of suspended ceilings (6-10mm)

● Raised floor construction (14mm and above)

● Used as roof sheathing panels (12-16mm)

● In construction of interior and exterior walls, floor and ceiling of light steel prefabricate buildings

● Fire protection of heavy steel buildings

● In furniture manufacturing (fireproof door, counter, cupboard, etc)

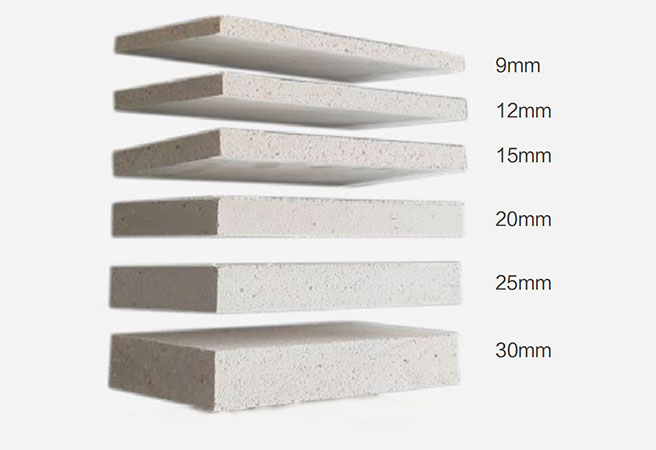

Dimension (mm) |

Thickenss (mm) |

1200x2440 |

8-20 |

1200*2400 |

8-20 |