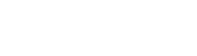

Drywall Profile Forming Machine Stud and Track

description1

description2

Key Features & Performance

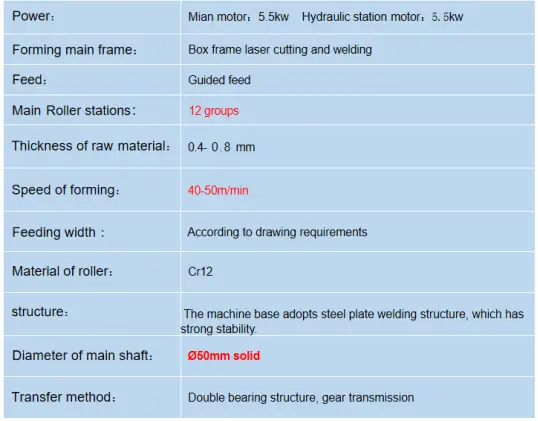

●Efficient Steel Profile Production: This machine can produce steel profiles with a thickness of 0.4-0.8 mm at a production capacity of 15-20m/min, making it ideal for various industries such as hotels, garment shops, and manufacturing plants.

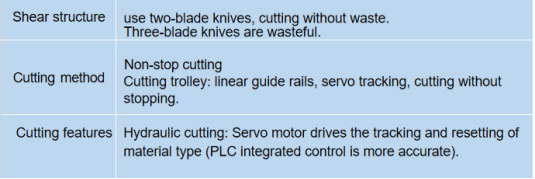

●Easy to Operate: With a user-friendly PLC (Delta) control system, this machine is simple to operate, reducing the learning curve for users.

●Durable Construction: The frame is made of high-grade steel, while the cutting blade, shaft, and roll are made of 45 steel, ensuring a long-lasting performance and minimizing maintenance needs.

●Comprehensive Support:The manufacturer provides online support, video technical support, and a 2-year warranty on the machine and core components, including the pressure vessel, motor, bearing, gear, pump, gearbox, engine, and PLC

●Global Availability:Showrooms are located in Canada, the United Kingdom, the United States, India, Mexico, and Morocco, making it convenient for customers to experience the machine firsthand and receive after-sales support.