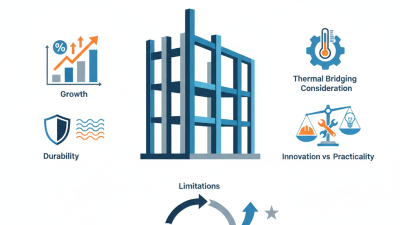

When it comes to construction and building projects, the choice of materials plays a crucial role. Aluminum Hat Channel is a versatile structural component widely used in various applications. According to a report by the Aluminum Association, aluminum products are projected to see a growth rate of 4.5% annually. This increase highlights the importance of finding efficient materials that enhance project durability.

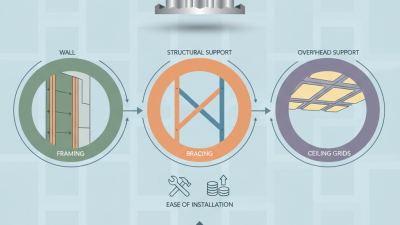

Aluminum Hat Channel provides strength while being lightweight. This feature makes it ideal for both interior and exterior uses. For instance, in the construction of walls or to support ceilings, its design allows for easy installation. However, many users often overlook proper installation techniques, which can lead to inefficiencies. While this material may seem straightforward, misunderstanding its applications can result in challenges.

The flexibility of Aluminum Hat Channel supports creative designs. However, builders must consider factors like environmental conditions and load bearing. These elements dictate how effectively the channel can function. Overall, despite its advantages, a thoughtful approach to its usage often needs reflection and careful planning.

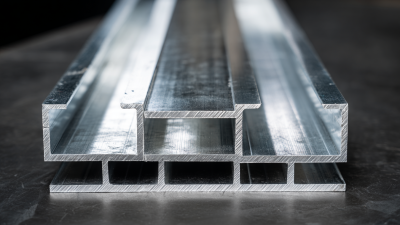

Aluminum hat channel is a versatile building material. It features a unique "hat" shape that provides strength and stability. This channel is often used in various construction projects, such as framing and drywall applications. It is lightweight yet durable, making it easier to handle on-site. The design allows for easy attachment of panels and other materials.

These channels find applications in both residential and commercial settings. They can be used to create support structures for ceilings and walls. Additionally, they can provide a base for mounting fixtures. In some cases, people may struggle with aligning the channels properly. This misalignment can lead to uneven surfaces. Reflecting on the assembly process can help improve overall quality.

Using aluminum hat channels also requires some planning. Consider the weight of the materials you intend to attach. The channels should be selected based on your project requirements. Choosing the right size is crucial. Many people overlook this detail, leading to complications later on. Simple adjustments can often make a significant difference in the final outcome.

When it comes to construction projects, aluminum hat channels offer numerous benefits. These channels are known for their lightweight yet durable nature. Using them can streamline the building process significantly. Their design allows for easy installation, which saves time and labor costs. This efficiency can be especially helpful for tight deadlines.

Another advantage is their excellent resistance to corrosion. Unlike other materials, aluminum hat channels withstand harsh weather conditions. They remain structurally sound even in extreme environments. This durability ensures that projects require fewer repairs and replacements over time. However, the initial investment is essential to think about. While the upfront cost might be higher, the long-term savings on maintenance can be worth it.

Finally, aluminum hat channels enhance the aesthetic appeal of structures. They can be painted or finished in various styles. This versatility allows for creative designs that suit different architectural needs. Though some may find the options limited initially, experimenting can lead to unique outcomes. Using these materials can elevate the overall quality of your project while also challenging traditional approaches.

Aluminum hat channels serve various purposes in construction and manufacturing. Understanding the key specifications is crucial. Typically, they come in standard sizes, such as 1-1/2 inches tall and 1-1/2 inches wide. The thickness of the channels usually ranges from 0.125 to 0.250 inches. According to the Aluminum Association, these specifications ensure strength while maintaining lightweight characteristics.

Weight per foot is another critical factor. A common aluminum hat channel weighs approximately 1.6 to 2.0 pounds per foot. The structural integrity is also defined by the ASTM standards, like ASTM B221. This standard outlines the dimensional and mechanical properties necessary for quality assurance. Despite these guidelines, not all manufacturers adhere to them strictly, leading to potential discrepancies in product quality.

Corrosion resistance is important as well. Aluminum naturally forms a protective oxide layer. However, in high-humidity environments, this layer might be compromised. Choosing alloys, such as 6063 or 6061, can enhance this property. Interestingly, the recycling aspect of aluminum makes it an eco-friendly choice, contributing to a sustainable building approach. Yet, the varying qualities in recycled aluminum can challenge project outcomes. Attention to these details is vital for success in using aluminum hat channels effectively.

When using aluminum hat channel in structural supports, installation techniques are crucial. Proper alignment ensures structural integrity. According to recent industry reports, nearly 70% of structural failures are due to improper installation techniques. Aluminum hat channels should be securely fastened to prevent misalignment during load-bearing applications. Investing time in accurate measurements can save costs down the line.

To begin, always check the dimensions of the hat channel. Any deviation can lead to significant issues. Use a level to maintain a straight reference line. It is essential to drill pilot holes to avoid cracks. Reports indicate that using screws rather than nails enhances the longevity of the installation. Be mindful of the environment during installation; aluminum reacts differently with various coatings. Ensure compatibility to minimize unexpected reactions.

Remember, if adjustments are needed, do not force components together. This can compromise the integrity of the structure. Allow time for adjustments. Learning from past installations is imperative. Each project holds unique challenges that may not fit standard practices. Reassessing techniques continuously is key for improvement in using aluminum hat channels effectively.

When incorporating aluminum hat channels into your projects, durability is key. These channels are versatile, but they require proper maintenance. Regular checks for corrosion can prolong their life. Applying a protective coating can also enhance resistance to environmental exposure.

Incorporating proper installation methods is essential. Ensure the channels are secured tightly to reduce stress points. Misalignment can lead to premature wear. Regular maintenance inspections should be part of your routine. Remove any debris that accumulates over time. This can help prevent moisture retention, a key factor in corrosion.

While aluminum is inherently durable, it is not indestructible. Watch for signs of denting or bending. These imperfections can weaken structural integrity. Consider using additional supports in high-stress areas. Refining your approach to installation and maintenance will enhance the overall performance of your hat channels. Observing these practices can save time and money in the long run.