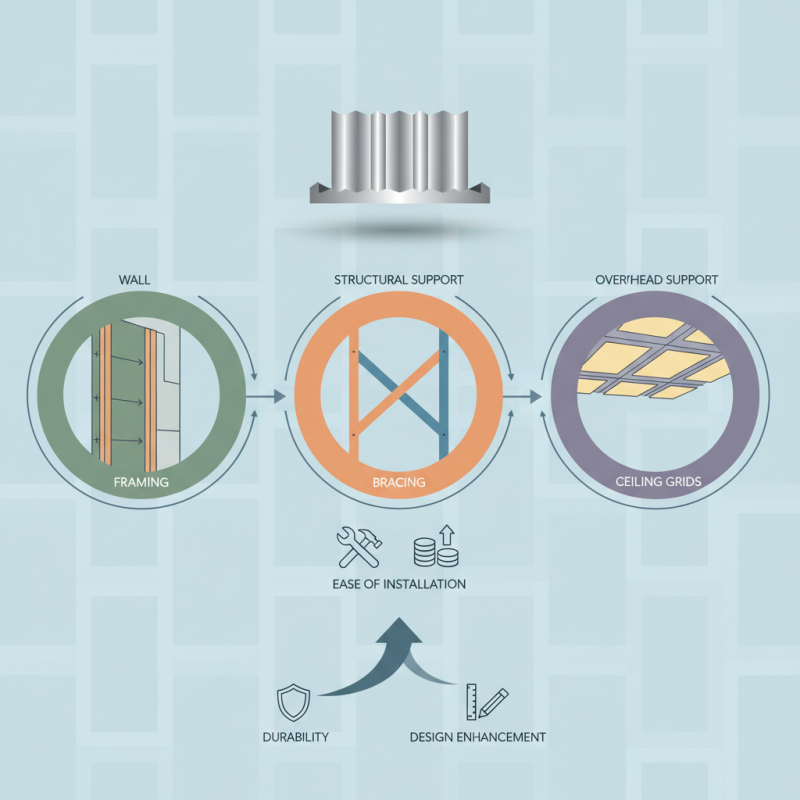

Aluminum Hat Channel is a versatile building material. It is lightweight yet strong. This unique shape provides excellent support and stability in construction projects.

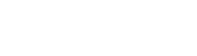

Using Aluminum Hat Channel can optimize various applications. Builders often appreciate its ease of installation and cost-effectiveness. However, not all constructions make the best use of this material. Understanding how to utilize it properly is essential for achieving desired outcomes.

Exploring different ways to implement Aluminum Hat Channel is crucial. It can serve in framing, bracing, and overhead support. Some users find themselves struggling with installation techniques. Reflecting on their experiences can lead to better practices. Overall, the right approach can enhance both durability and design in construction.

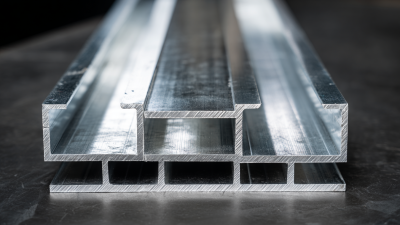

Aluminum hat channel is a versatile material widely used in construction. Its lightweight yet durable design makes it ideal for various applications. According to a report by the Aluminum Association, aluminum's strength-to-weight ratio is twice that of steel, making it a popular choice for both commercial and residential projects.

The benefits of using aluminum hat channels extend beyond just weight. They resist corrosion, which is essential for structures in harsh environments. A study by the National Association of Home Builders found that materials resistant to corrosion can increase the lifespan of a building by up to 20%. Using aluminum also offers energy savings, as it reflects heat and can reduce cooling costs.

However, working with aluminum hat channels does come with challenges. The material can be prone to bending under heavy loads if not supported correctly. This requires careful planning during installation. Additionally, welding aluminum requires specific skill sets, and improper techniques can weaken the joint. It's important to consider these factors to optimize construction outcomes.

When working with aluminum hat channel, having the right tools is crucial. Essential tools include a saw for precise cuts. A miter saw can ensure accuracy in angles. You'll also need a drill for fastening. Choose drill bits suitable for metal to avoid frustration. A level is vital for ensuring everything lines up correctly. Attention to detail at this step pays off later.

Materials play a key role too. Choose high-quality aluminum for strength. Thin or flimsy materials will not hold up well over time. Look for rivets and screws that are compatible with aluminum. They should resist corrosion. Don't forget safety gear, like gloves and goggles. Working with metal can be dangerous without proper protection.

Here are some tips: Always double-check your measurements before cutting. A small mistake can lead to waste. When drilling, apply steady pressure. Too much force can damage the material. Finally, keep your workspace organized to stay efficient. An untidy environment can lead to misplaced tools and materials.

Installing aluminum hat channel can enhance structural integrity in various construction projects. This lightweight material is ideal for securing drywall, insulation, and other materials with ease. According to industry data, using aluminum hat channels can improve load distribution by 30%, making them a reliable choice.

When you begin installation, ensure you have the right tools. A level, measuring tape, and a drill are essential. Measure your space accurately before cutting the channel to size. Remember, precision is key. A mistake in measurement can lead to unnecessary waste and extra work later.

Tips: Use a stud finder to locate wall studs. This helps ensure a sturdy attachment. Mark these locations before you cut your channels. Additionally, consider double-checking your work after initial installations. Mistakes can happen, and it’s better to fix them early.

During installation, secure the channels at regular intervals. Over-tightening screws can warp the aluminum, leading to potential issues. Take a moment to review your installation process. Look for spots that may need reinforcement. Sometimes, areas might require additional support. Don't hesitate to revisit your work if you feel uncertain.

Aluminum hat channel is frequently used in various construction applications. It is lightweight yet strong, making it ideal for framing. Builders often use it for interior wall systems. The channel provides excellent structural support while remaining easy to handle.

Another common application is in ceiling grids. The hat channel can create a clean, modern look. In this case, precision is key. Misalignment can lead to an uneven surface. Using aluminum hat channel in external façades is also popular. It is resistant to corrosion and great for cladding materials.

While aluminum hat channel offers many benefits, it's important to consider its limitations. Not all environments are suitable for its use. The installation process requires careful planning and measurement. Small errors can compromise the integrity of the structure. A thorough understanding of its properties helps avoid mistakes. Make sure to review guidelines and best practices before starting your project.

To ensure longevity for aluminum hat channel installations, regular maintenance is essential. Inspect the channels periodically for signs of wear or corrosion. Even though aluminum is resistant, it can still degrade over time. Pay attention to areas where moisture might collect. Standing water can lead to unexpected damage.

Cleaning is also crucial. Use a gentle brush and a mild detergent to remove dirt. Avoid harsh chemicals that can harm the aluminum. A thorough cleaning can prevent buildup that compromises structural integrity. Simple maintenance tasks can prolong the life of the installation significantly.

Consider environmental factors that may affect performance. Areas with high humidity or nearby saltwater can increase the need for maintenance. Regular checks and cleaning become even more important in these conditions. Sometimes, it is easy to overlook small issues until they become big problems. Being proactive can save time and money in the long run.

| Maintenance Tip | Description | Frequency | Potential Issues |

|---|---|---|---|

| Regular Cleaning | Remove dirt and debris to prevent corrosion. | Monthly | Corrosion, Surface Damage |

| Inspect for Damage | Check for dents, cracks, or warping. | Quarterly | Structural Integrity Issues |

| Lubricate Fasteners | Apply a suitable lubricant to bolts and screws. | Bi-Annually | Rust, Difficulty in Maintenance |

| Check Alignment | Ensure that the hat channel is level and correctly positioned. | Annually | Misalignment, Stress on Structure |

| Protect from Moisture | Ensure proper drainage and ventilation around installations. | Ongoing | Corrosion, Water Damage |