Metal studs have gained significant traction in the construction industry over the past few years. According to a report by ResearchAndMarkets, the global metal framing market is projected to reach $25 billion by 2025. This growth is largely due to the advantages metal studs offer over traditional wood framing. They are lighter, more durable, and resistant to pests and moisture.

The use of metal studs can reduce construction time by up to 50%. This efficiency translates into lower labor costs and faster project completion. Furthermore, metal studs provide superior structural integrity, which is critical in earthquake-prone regions. However, some builders hesitate due to concerns about the difficulty in handling and installation.

Despite some challenges, embracing metal studs can lead to long-term savings and enhanced building performance. In a sector where cost-effectiveness and sustainability are paramount, metal studs offer a compelling advantage. A shift towards this innovative material could redefine construction standards and practices.

Metal studs are essential in modern construction. They offer strength and durability as a framing material for walls and ceilings. Unlike wood studs, metal studs resist warping, termites, and moisture, making them ideal for various environments. Their lightweight nature also makes them easy to handle, reducing labor costs during installation.

When using metal studs, it's important to account for potential thermal bridging. This occurs when metal conducts heat away from the building, potentially reducing energy efficiency. Also, be mindful of fire safety regulations as metal can conduct heat. Proper insulation and drywall installation can mitigate such issues.

Tips: Always check the local building codes. Ensure that metal studs meet all necessary requirements. Bear in mind that while metal studs are durable, poor handling can lead to bent or damaged frames. Inspect materials before use to avoid future complications.

Metal studs are gaining popularity in construction due to their strength and durability. Unlike traditional wood studs, metal studs resist warping, cracking, and shrinking. They can withstand harsh weather conditions, making them a reliable choice for various projects. Metal studs tend to be lighter, yet they provide superior structural integrity. This makes them an attractive alternative to wood, especially in commercial buildings.

When comparing metal studs and wood studs, consider the environment. Metal studs are often made from recycled materials, making them more eco-friendly. This can be an important factor for builders focused on sustainability. Additionally, metal studs can simplify the construction process with their precision cuts and uniform shapes. However, they may require special tools for installation, which could pose challenges for some builders.

Tips: Always double-check measurements before cutting metal studs. This can save time and reduce waste. When storing metal studs, keep them dry to avoid rust. Remember, while metal studs have many advantages, they can be more expensive than wood. Reflect on your project's budget to make an informed choice.

This chart compares the strength and durability of metal studs versus traditional wood studs. Metal studs demonstrate significantly higher strength (50 psi) and durability (up to 50 years) compared to wood studs (30 psi and 20 years), illustrating the advantages metal studs offer in construction settings.

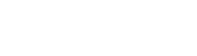

Metal studs have gained popularity in the construction industry due to their cost efficiency and sustainability. According to a report by the American Iron and Steel Institute, the use of steel studs can save up to 30% in material costs compared to traditional wood framing. This reduction in cost stems from the precision of metal studs, which require less labor and lead to faster construction times.

Sustainability is another key advantage. Metal studs are made from recycled materials and can be recycled again at the end of their life cycle. The metal framing process generates less waste, making it environmentally friendly. A study by the Steel Market Development Institute highlighted that 70 million tons of steel were recycled in 2018, reinforcing its green credentials.

Tip: When selecting materials for a project, consider the lifecycle of your choices. Opt for materials that reduce waste and promote sustainability.

Metal studs are not without challenges. They can be more difficult to work with when it comes to certain installations like electrical and plumbing. Some workers may find them less forgiving than wood. Adjusting to these differences can be frustrating. Ensuring that all workers are trained properly can help mitigate these issues.

Tip: Provide hands-on training sessions for your team on working with metal studs. This investment can save time and reduce mistakes later.

The use of metal studs in commercial building projects has seen a significant rise in recent years. According to industry statistics, over 60% of new commercial structures now utilize metal framing. This shift towards metal studs offers many benefits like durability and resistance to insects and mold. However, the initial installation costs can be higher than traditional wood studs.

Metal studs are lightweight and easier to install, which can lead to faster construction times. Still, not all builders have embraced them fully. Some express concerns over the need for specialized tools. Additionally, while metal studs resist fire, they can conduct heat, which poses challenges during insulation. Overall, the growing preference for metal studs marks a change in construction practices. Yet, it highlights the importance of continuous evaluation of materials in differing contexts.

| Project Type | Percentage of Metal Stud Use | Cost Savings (%) | Sustainability Rating |

|---|---|---|---|

| Office Buildings | 75% | 10% | High |

| Retail Spaces | 65% | 8% | Medium |

| Healthcare Facilities | 70% | 12% | High |

| Educational Institutions | 80% | 15% | Very High |

| Hospitality | 60% | 9% | Medium |

Metal studs are becoming a popular choice in modern construction. Their installation involves several specific techniques that ensure structural integrity and efficiency. The process begins with careful planning and measurement. Accurate measurements are crucial to prevent material waste. Installing metal studs generally requires basic tools like a level, stud finder, and framing square.

Once the layout is determined, starting the framing is essential. Vertical studs must be placed correctly. Adequate spacing, typically 16 or 24 inches apart, enhances stability. It’s important to secure studs to the floor and ceiling tracks properly. A study by the Steel Framing Alliance shows that metal studs are about 30% lighter than wood but provide the same load-bearing capabilities.

While the process seems straightforward, it requires attention to detail. Issues may arise if studs are misaligned or not secured adequately. Additionally, the availability of various gauges adds complexity. Each project may require different strengths of metal studs. Understanding these factors can lead to better outcomes. Many builders still face challenges adapting to these newer methods. A shift in mindset may be necessary to embrace the benefits.