In the realm of modern construction, ensuring structural integrity has become paramount, especially with the increasing demand for resilient and sustainable building materials. As highlighted by the recent Freedonia Group report, the aluminum building materials market is projected to reach $49 billion by 2025, showcasing a robust growth driven by innovations in material science.

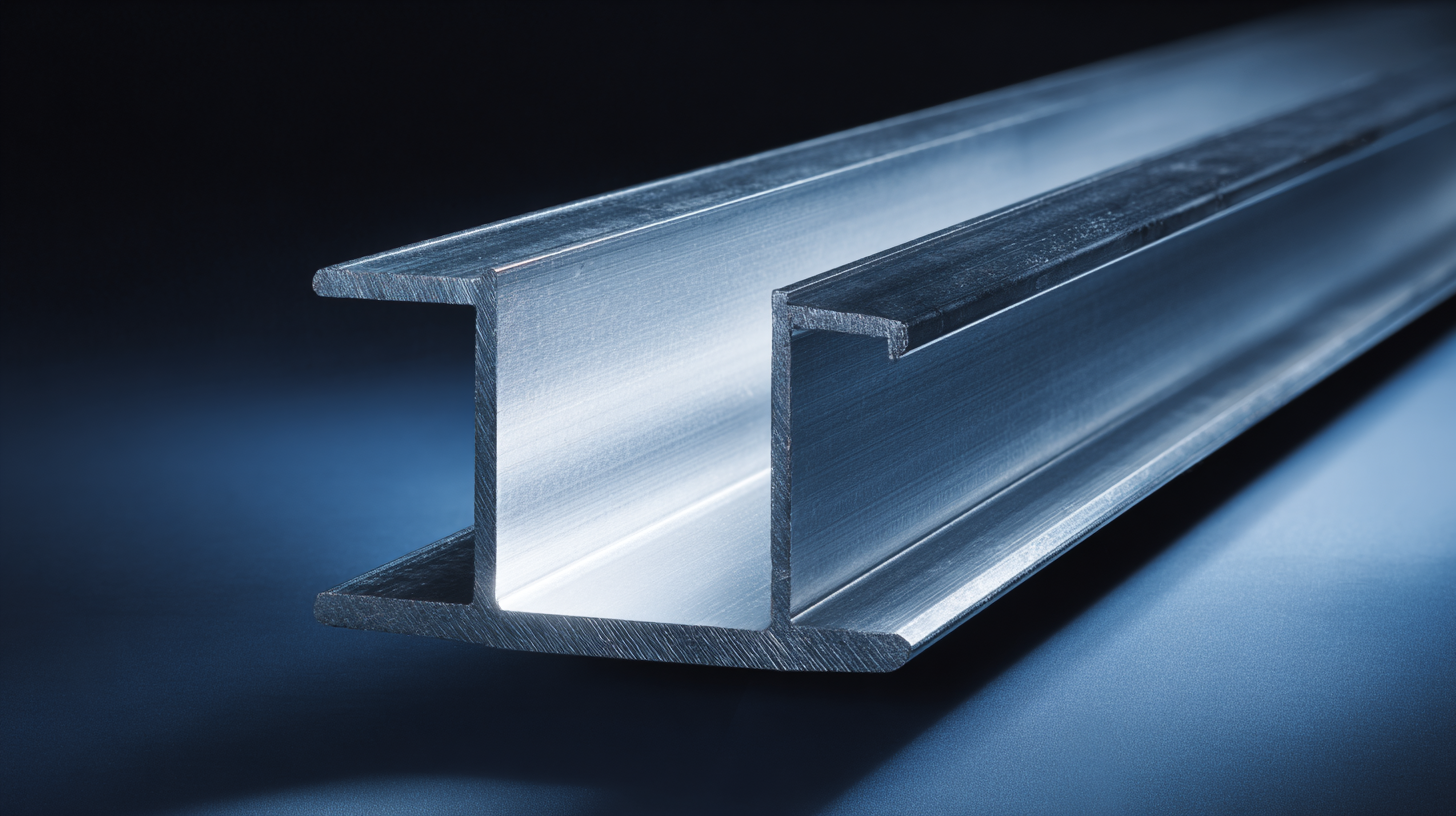

Among these advancements, Aluminum Hat Channels stand out as a critical component, providing exceptional strength and versatility while minimizing weight. Their unique design not only enhances load distribution but also facilitates efficient installation, making them a preferred choice in various applications, from commercial buildings to residential projects. This article delves into the pivotal role of Aluminum Hat Channels in maximizing structural integrity, exploring their benefits, applications, and the future of construction methodologies.

Aluminum hat channels are integral to contemporary construction design, serving multiple essential functions that enhance structural integrity and efficiency. Their unique shape provides superior load distribution, making them ideal for use in walls and ceilings. This design allows for better reinforcement of materials, ensuring that structures remain stable and secure over time. Additionally, aluminum is inherently lightweight, which simplifies the handling and installation process, ultimately reducing labor costs and time.

Beyond structural support, aluminum hat channels also play a significant role in modern sustainability efforts. Their durability and resistance to corrosion ensure longevity, which minimizes the need for replacements and extensive repairs. This not only benefits the environment by reducing waste but also enhances the overall cost-effectiveness of construction projects. Furthermore, their compatibility with various insulation materials allows for improved energy efficiency in buildings, contributing to a lower carbon footprint and compliance with contemporary energy regulations.

Aluminum hat channels have emerged as a pivotal component in modern construction, offering unparalleled advantages in structural support. According to a report by the Aluminum Association, structures utilizing aluminum components can reduce overall weight by up to 30% compared to traditional steel counterparts, significantly enhancing structural integrity without compromising durability. This weight reduction is particularly beneficial in large-scale construction projects, where lower weight leads to decreased load on foundations and framing systems, allowing for larger spans and more flexible design options.

Moreover, aluminum's corrosion resistance plays a critical role in extending the lifespan of construction elements. Research from the U.S. Department of Transportation indicates that aluminum structures can last up to 40% longer than their steel equivalents in harsh environments, reducing the need for frequent maintenance and replacement. This durability not only ensures safety and reliability but also contributes to overall cost savings for project developers. By integrating aluminum hat channels into their designs, engineers and builders can optimize their projects for both efficiency and longevity, positioning aluminum as a go-to material in the evolution of contemporary construction.

Aluminum hat channels have emerged as a crucial component in modern construction, especially when compared to traditional building materials like wood and steel. One significant advantage of aluminum hat channels is their lightweight nature, which not only simplifies transportation and installation but also reduces the overall load on structural frameworks. This intrinsic property allows for more flexible design options while maintaining high structural integrity, which is often a challenge with heavier materials. Furthermore, aluminum's resistance to corrosion enhances the durability of structures, making it a more sustainable choice for long-term use.

In contrast, traditional materials such as steel and wood present limitations. Steel, while strong, is prone to rust and requires protective coatings, which can add to maintenance costs over time. Wood, although widely used, is susceptible to warping, splitting, and pest infestations, impacting the longevity of the structure. By contrast, aluminum hat channels offer a consistent performance, providing a reliable solution for various construction needs. The combination of strength, durability, and versatility of aluminum hat channels positions them as a superior alternative, aligning with the evolving demands of modern architectural practices.

Aluminum hat channels play a pivotal role in enhancing the structural integrity of modern buildings. When integrating these channels into a design, it’s essential to consider various factors such as load-bearing capacity, corrosion resistance, and compatibility with other building materials. Their unique shape and lightweight nature not only minimize bulk but also provide exceptional strength where it’s needed most.

Aluminum hat channels play a pivotal role in enhancing the structural integrity of modern buildings. When integrating these channels into a design, it’s essential to consider various factors such as load-bearing capacity, corrosion resistance, and compatibility with other building materials. Their unique shape and lightweight nature not only minimize bulk but also provide exceptional strength where it’s needed most.

Tips: When selecting aluminum hat channels, ensure they are treated for corrosion resistance, especially in environments prone to moisture. Additionally, consult structural engineers to determine the optimal spacing and placement within the framework for maximum load distribution.

Another key consideration is the integration process itself. Proper alignment and secure fastening can prevent potential structural failures down the line. Employing advanced fastening techniques and regularly inspecting integration points can preserve the longevity of the structure.

Tips: Use non-corrosive fasteners to prevent chemical reactions that could weaken the attachment points. Regular maintenance checks on the structural connections can help identify any issues before they compromise the integrity of the building.

The global market for atomized aluminum powder is forecasted to reach $307.3 million in 2024 and is expected to grow significantly, escalating to $4.209 billion by 2025, with an astonishing CAGR of 37.8% projected up to 2032. This remarkable growth is primarily driven by the rising demand for non-residential applications, particularly in sectors such as refrigeration facilities, industrial buildings, and institutional architecture. Such advancements underscore a pivotal shift in the construction industry towards innovative materials like aluminum hat channels that enhance structural integrity and sustainability.

Additionally, the demand for sustainable building materials is escalating due to increasingly stringent environmental regulations. By 2034, the global geopolymer cement market is anticipated to grow to an estimated $14.5 billion, reflecting a 19% increase from 2025. This transition towards eco-friendly materials aligns with future trends in construction, where innovations in aluminum applications are playing a critical role in delivering not only durability but also improved energy efficiency in modern buildings. As the construction landscape evolves, aluminum hat channels are poised to become essential components in driving the industry's shift towards smarter and more sustainable building practices.