In the construction industry, selecting the appropriate materials is crucial for both structural integrity and cost-effectiveness.

Steel studs, known for their durability and flexibility, have increasingly become a preferred choice over traditional wood framing in commercial and residential projects.

According to a report by IBISWorld, the metal stud framing market is expected to reach $6 billion by 2025, reflecting a growing trend towards lightweight, fire-resistant, and environmentally sustainable options.

Additionally, the Steel Framing Alliance highlights that steel studs can enhance energy efficiency and reduce waste, aligning with modern building practices that prioritize sustainability.

This article will guide you through the key factors to consider when choosing steel studs for your construction project, ensuring that you make an informed decision that meets both your performance and budgetary requirements.

Steel studs, known for their durability and flexibility, have increasingly become a preferred choice over traditional wood framing in commercial and residential projects.

According to a report by IBISWorld, the metal stud framing market is expected to reach $6 billion by 2025, reflecting a growing trend towards lightweight, fire-resistant, and environmentally sustainable options.

Additionally, the Steel Framing Alliance highlights that steel studs can enhance energy efficiency and reduce waste, aligning with modern building practices that prioritize sustainability.

This article will guide you through the key factors to consider when choosing steel studs for your construction project, ensuring that you make an informed decision that meets both your performance and budgetary requirements.

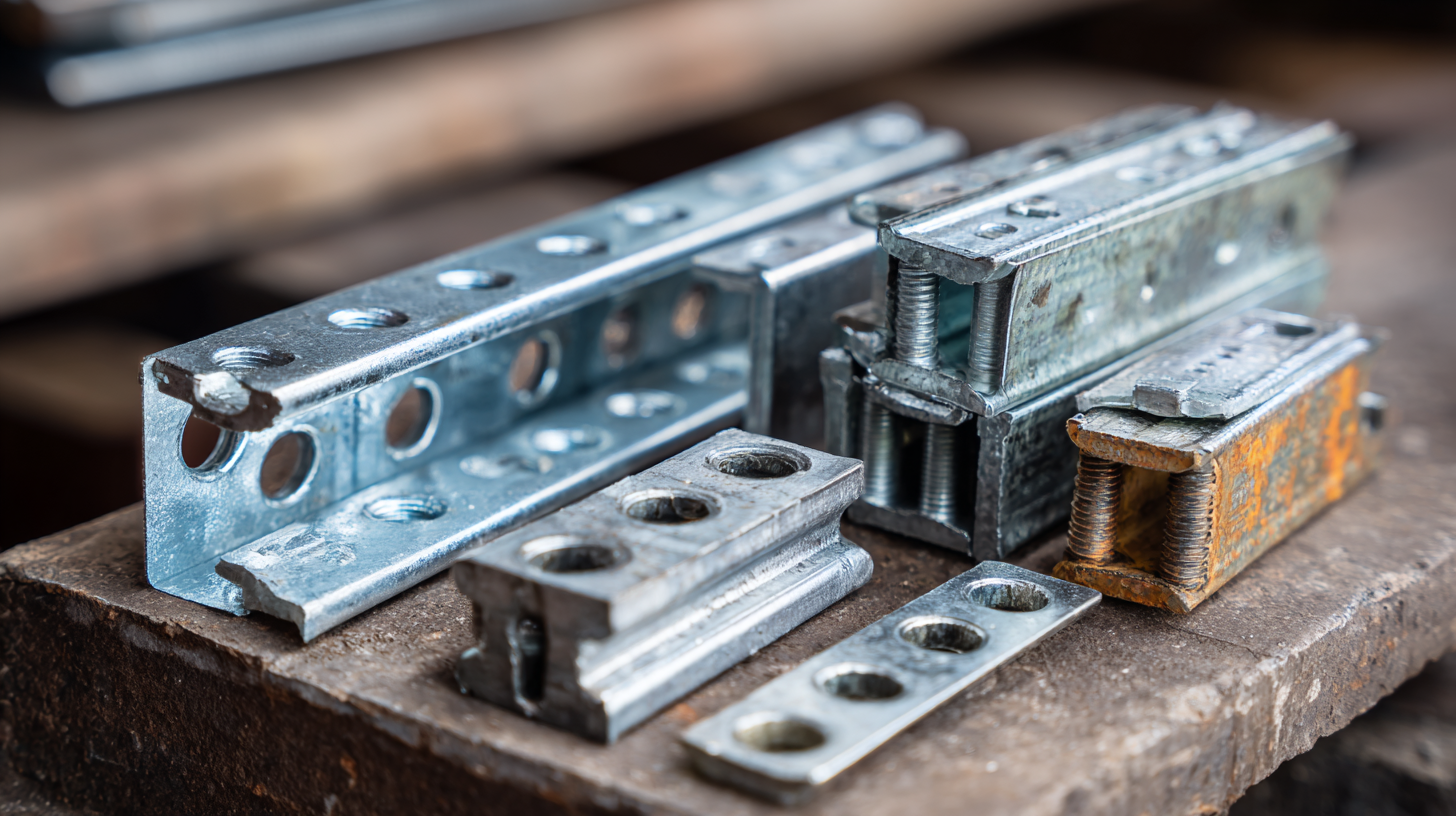

When selecting steel studs for your construction project, it’s crucial to understand the different grades available. Steel studs are often categorized by their yield strength and composition, impacting their suitability for various applications. Common grades include mild steel (20ksi), structural steel (33ksi), and high-strength steel (50ksi), each designed for specific structural integrity and load-bearing requirements. Knowing the grade you need helps ensure your project meets both safety and durability standards.

Always consider the specific demands of your construction project when selecting a steel stud grade. For example, if you’re working on a load-bearing wall, opt for higher-grade studs to ensure strength and stability. Conversely, for non-load-bearing applications, lightweight mild steel may suffice.

Another factor to weigh is the environment where the studs will be installed. Exposure to moisture or corrosive elements may require opting for galvanized or stainless steel grades, which offer enhanced resistance and longevity. Regularly consulting with structural engineers can provide additional insights tailored to your project’s needs.

When embarking on a construction project, evaluating the structural strength required is paramount to choosing the right steel studs. According to the American Institute of Steel Construction, the load-bearing capacity of steel studs can vary significantly based on their gauge, span, and the weight they need to support. For instance, 20-gauge steel studs can typically support a maximum load of 33-40 pounds per linear foot, making them suitable for non-load-bearing walls, whereas 16-gauge studs can handle upwards of 50 pounds, ideal for heavier structures. Understanding these specifications helps in making informed decisions tailored to the unique demands of your project.

**Tip:** Always consider the wall height and load type (such as dead loads or live loads) when determining stud specifications. Utilizing engineered software like Sefaira for performance modeling can assist in accurately estimating the structural requirements.

In addition to gauge and load capacities, another critical evaluation factor is corrosion resistance. A recent study published in the Journal of Construction Engineering and Management indicates that untreated steel studs can suffer from significant degradation in moist environments. Opting for galvanized or stainless steel studs can prolong durability and maintain structural integrity. This decision not only impacts the life span of your project but can also influence maintenance costs over time.

**Tip:** Assess environmental conditions and select steel studs with appropriate coatings for optimal performance and longevity.

This chart illustrates the structural strength (measured in pounds per square inch, PSI) of different types of steel studs commonly used in construction projects. The data reflects the typical strength characteristics that should be evaluated when selecting steel studs for your project.

When undertaking a construction project, selecting the appropriate steel studs is crucial for durability and performance. Among the available options, pre-galvanized and galvanized steel studs are commonly compared. Pre-galvanized studs are coated with a zinc layer before the manufacturing process, offering adequate protection against rust and corrosion for indoor applications or areas with minimal moisture exposure. Their availability in various sizes and shapes makes them a popular choice for lightweight structures.

On the other hand, galvanized steel studs undergo a hot-dipping process after fabrication, resulting in a thicker, more resilient zinc coating. This additional protection makes them better suited for outdoor environments or high-moisture areas, where corrosion resistance is essential. While galvanized steel studs may have a higher initial cost, their long-term benefits often outweigh the upfront investment, especially in challenging conditions. Ultimately, the choice between pre-galvanized and galvanized steel studs depends on the specific requirements of your project, emphasizing the importance of considering environmental factors and the intended use of the structure.

| Attribute | Pre-Galvanized Steel Studs | Galvanized Steel Studs |

|---|---|---|

| Corrosion Resistance | Moderate | High |

| Cost | Lower | Higher |

| Weight | Lighter | Heavier |

| Durability | Moderate | High |

| Applications | Interior Projects | Exterior and High Moisture |

When considering the cost-effectiveness of steel studs in modern construction, it is essential to evaluate both the initial investment and long-term benefits. According to a report by the Steel Framing Industry Association, the use of steel studs can reduce overall construction costs by up to 30% due to their lightweight nature and ease of handling. Unlike traditional wood framing, steel studs do not warp, shrink, or swell, which minimizes the risk of expensive repairs down the line. This durability is especially critical in areas prone to moisture or pest issues.

Moreover, steel studs offer significant benefits related to sustainability and energy efficiency. The American Iron and Steel Institute indicates that steel is one of the most recycled materials globally, with over 90% of steel being reused in new construction projects. Additionally, buildings framed with steel often achieve higher energy efficiency ratings, leading to reduced utility costs. In effect, while the upfront costs of steel studs may be slightly higher than wood, their longevity and potential for energy savings make them a prudent investment for modern construction projects.

When selecting steel studs for your construction project, understanding the load-bearing needs is crucial. Steel studs come in various sizes, and their dimensions significantly impact their load-bearing capabilities. For instance, 3-5/8 inch studs are commonly used for interior framing, while 6-inch or thicker studs are often required for exterior walls or any structure that will support heavier loads. It’s essential to evaluate the specific requirements of your project, including the type of materials that will be used in the construction and the overall design of the building.

Additionally, factors such as spacing and attachment methods will play a role in determining the appropriate size of the steel studs. Standard practice often involves spacing studs 16 or 24 inches apart, but this can vary based on load requirements. A greater load may necessitate closer spacing or heavier gauge studs, which can increase both stability and safety. Thus, collaborating with a structural engineer is advisable to ensure that the selected steel stud sizes align with the intended load-bearing specifications. Properly choosing the right steel studs not only enhances the structural integrity of the construction project but also contributes to its long-term performance.