The Aluminum Hat Channel has emerged as an essential component in various construction and DIY projects, offering both structural integrity and aesthetic appeal. According to a recent industry report by the Aluminum Association, the demand for aluminum products, including hat channels, has seen a steady increase of approximately 5% annually, underscoring the material's popularity and versatility. With an ever-growing emphasis on lightweight and corrosion-resistant materials, the Aluminum Hat Channel is especially favored in applications such as wall framing, ceiling installation, and as a supportive framework for other materials.

Expert in the field, Dr. Aaron Thompson, a structural engineer at the National Institute of Aluminum Research, notes, “The Aluminum Hat Channel not only enhances the strength of constructions but also contributes significantly to energy efficiency.” This insight highlights the dual benefits of using aluminum hat channels: they not only provide robust support but also help in reducing overall project costs through improved energy performance. As DIY enthusiasts and professionals alike increasingly recognize these advantages, understanding the uses, benefits, and installation tips for Aluminum Hat Channels becomes crucial for optimizing any project’s outcome.

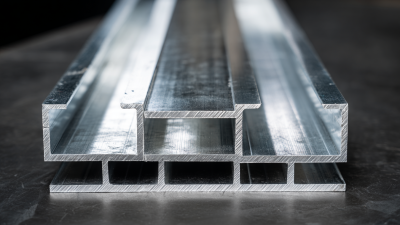

Aluminum hat channels are a versatile type of structural component recognized for their distinctive U-shaped profile. These channels are primarily made from high-quality aluminum, known for its lightweight yet durable nature. This unique shape allows hat channels to provide excellent support and stability in various applications, making them ideal for framing, wall systems, and even as reinforcement in ceilings. Their intrinsic resistance to corrosion gives them a significant advantage in outdoor projects or environments with high moisture levels.

One of the defining characteristics of aluminum hat channels is their ease of installation. The lightweight material simplifies handling and positioning, which is particularly beneficial for DIY enthusiasts. Additionally, the channels can be easily cut to size, accommodating various project requirements without the need for specialized tools. Their compatibility with different fastening methods, such as screws, rivets, or welds, further enhances their usability in diverse settings. This adaptability, combined with the material's inherent strength, underscores the practicality of aluminum hat channels in both amateur and professional construction projects.

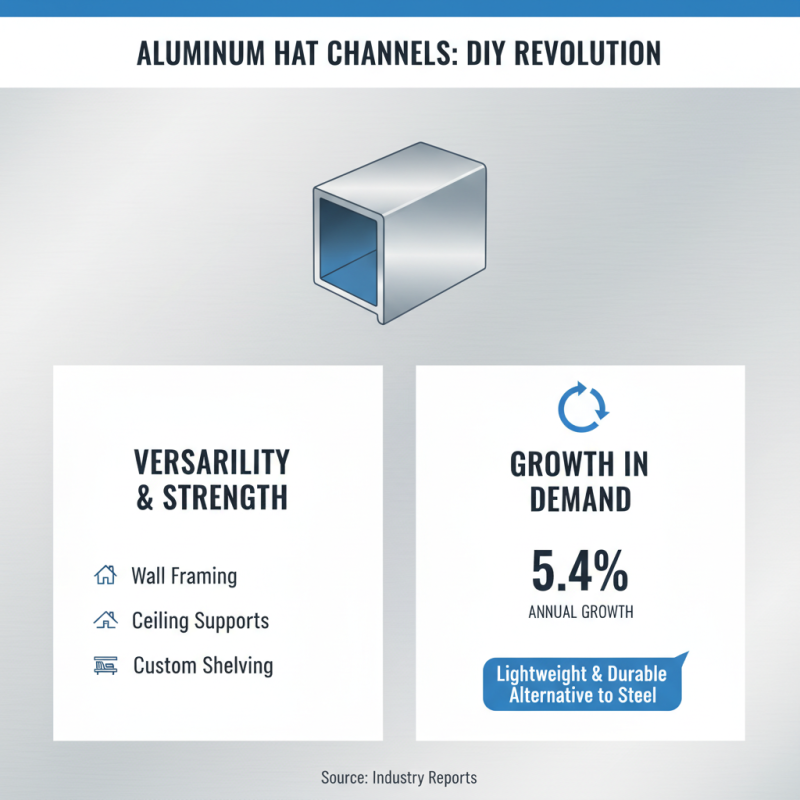

Aluminum hat channels have become increasingly popular in various DIY projects due to their versatility and unique structural properties. These channels, characterized by their “hat” shape, provide a robust framing solution that is ideal for applications such as wall framing, ceiling supports, and even custom shelving units. According to industry reports, the demand for aluminum construction materials has surged, showing a growth rate of approximately 5.4% annually, driven by their lightweight yet strong characteristics that offer durability without the added weight of traditional steel alternatives.

In DIY projects, aluminum hat channels serve multiple purposes. They can be easily cut and shaped to fit specific project needs, making them ideal for creative applications. For example, they are often used to create custom frames for artwork or shelving solutions that require substantial support without compromising on design aesthetics. Research indicates that the use of aluminum in residential construction not only enhances energy efficiency but also contributes to lowering overall project costs. Furthermore, with an average lifespan of 50 years when properly maintained, aluminum hat channels significantly reduce the need for replacements, making them a cost-effective choice for DIY enthusiasts looking to create lasting projects.

Aluminum hat channels are increasingly recognized for their advantages in construction, particularly in DIY projects. One of the primary benefits of using aluminum is its resistance to corrosion. Unlike steel, aluminum does not rust, making it an ideal choice for applications in humid or outdoor environments where moisture can be a concern. This durability ensures that the structures built with aluminum hat channels have a longer lifespan, reducing the need for repairs and replacements over time.

Another significant advantage is the lightweight nature of aluminum. This quality makes it easier to handle and install, allowing DIY enthusiasts to work with it without the need for heavy machinery or extensive manpower. Additionally, aluminum can be easily cut and shaped to fit specific project needs, providing versatility that other materials may lack. The inherent strength of aluminum hat channels also allows them to support significant weight without bending or breaking, making them suitable for various applications, from framing to structural supports. Overall, the use of aluminum hat channels offers a practical solution for both strength and ease of use in construction projects.

Installing aluminum hat channels can enhance the structural integrity and aesthetic appeal of various DIY projects. These channels, renowned for their lightweight yet durable nature, provide excellent support for wall coverings, ceilings, and other applications. To ensure a successful installation, it’s important to follow a step-by-step guide. Begin by measuring the space where you intend to install the hat channels, ensuring precise dimensions for optimal fit. Next, select the appropriate size of hat channel based on the weight and type of materials it'll support; typically, a channel width of 1.5 to 2 inches is sufficient for standard applications.

Before installation, gather essential tools such as a level, drill, screws, and measuring tape. When installing, mark the positions on the wall to ensure uniformity and use a level to maintain straightness. Securing the channels to the framing studs offers better stability, and it’s advisable to use screws rather than nails for enhanced holding strength. According to industry reports, properly installed hat channels can improve insulation and reduce sound transmission, making them ideal for residential and commercial spaces.

**Tips:** For best results, consider pre-drilling holes to prevent the aluminum from bending during installation. Additionally, when cutting the channels to size, a metal saw or snips can provide a clean edge, ensuring a professional finish. Always wear safety goggles to protect your eyes during the cutting process. Checking local building codes can also help comply with regulations and promote a safer installation environment.

Aluminum hat channels are renowned for their durability and lightweight characteristics, making them an excellent choice for various DIY projects. However, to maximize their lifespan and maintain their structural integrity, proper maintenance is essential. According to a report by the Aluminum Association, aluminum has a natural resistance to corrosion due to the formation of a protective oxide layer. This means that, while aluminum hat channels are low-maintenance, they still benefit from regular cleaning to remove dirt and debris that can degrade this protective layer over time.

For optimal longevity, it is advisable to inspect aluminum hat channels periodically for any signs of wear or damage. Ensuring that the channels are free from moisture buildup can prevent potential corrosion issues. If the surface is scratched or damaged, an aluminum-specific touch-up paint can be utilized to restore the protective layer. Industry studies suggest that routine maintenance checks can extend the lifespan of aluminum components by up to 50%, enhancing their performance in both structural and aesthetic applications. Utilizing these maintenance tips will not only preserve the functionality of aluminum hat channels but also enhance the overall integrity and appearance of your DIY projects.